Danglers

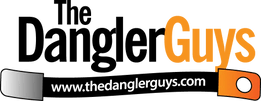

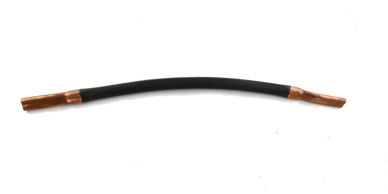

Volcanized Dangler

Volcanized Dangler

Volcanized Dangler

- The Ultimate Dangler

- 1.00″ OD insulation

- 1.125″ OD inside barrel

- Always flexible

- Custom formulated compound

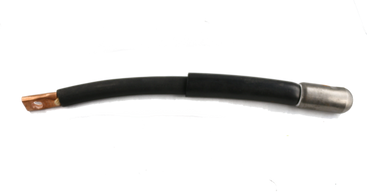

Plastisol Dangler

Volcanized Dangler

Volcanized Dangler

- 0.88″ OD EPDM Jacket

- 1.125″ OD inside barrel

- Extremely durable

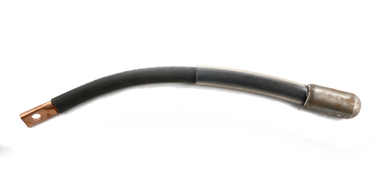

Full PVC Dangler

Volcanized Dangler

Full PVC Dangler

- 1″ OD passes through bearing hole and reduces wear

- Recommended for all size parts and loads

PVC Dangler

Plain Dangler

Full PVC Dangler

- Most common

- 0.88″ OD EPDM Jacket

- Tight Fit PVC – sealed at head and will not trap solution

- Recommended for all size parts and loads

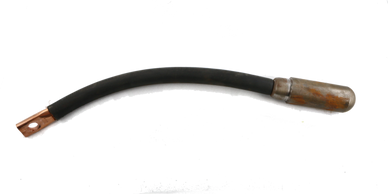

Plain Dangler

Plain Dangler

Plain Dangler

- 0.88″ OD EPDM Jacket

- Medium Abrasion Resistance

- Works well for small to medium sized parts

Mini Dangler

Plain Dangler

Plain Dangler

- Pre Made at 24″

- For small or sample barrel applications

Custom Jumpers

Custom Jumpers

Custom Jumpers

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.